Single-stage glanded centrifugal pump in monobloc design for an installation on a base with integrated frequency converter for an electronic control for constant or variable differential pressure (Δp-c/Δp-v). The CronoBloc BL-E has been predominantly designed for pumping heating water (acc. to VDI 2035), cold water and water/glycol mixtures without abrasive substances in heating, air-conditioning and cooling systems.

Design

- Single-stage low-pressure centrifugal pump

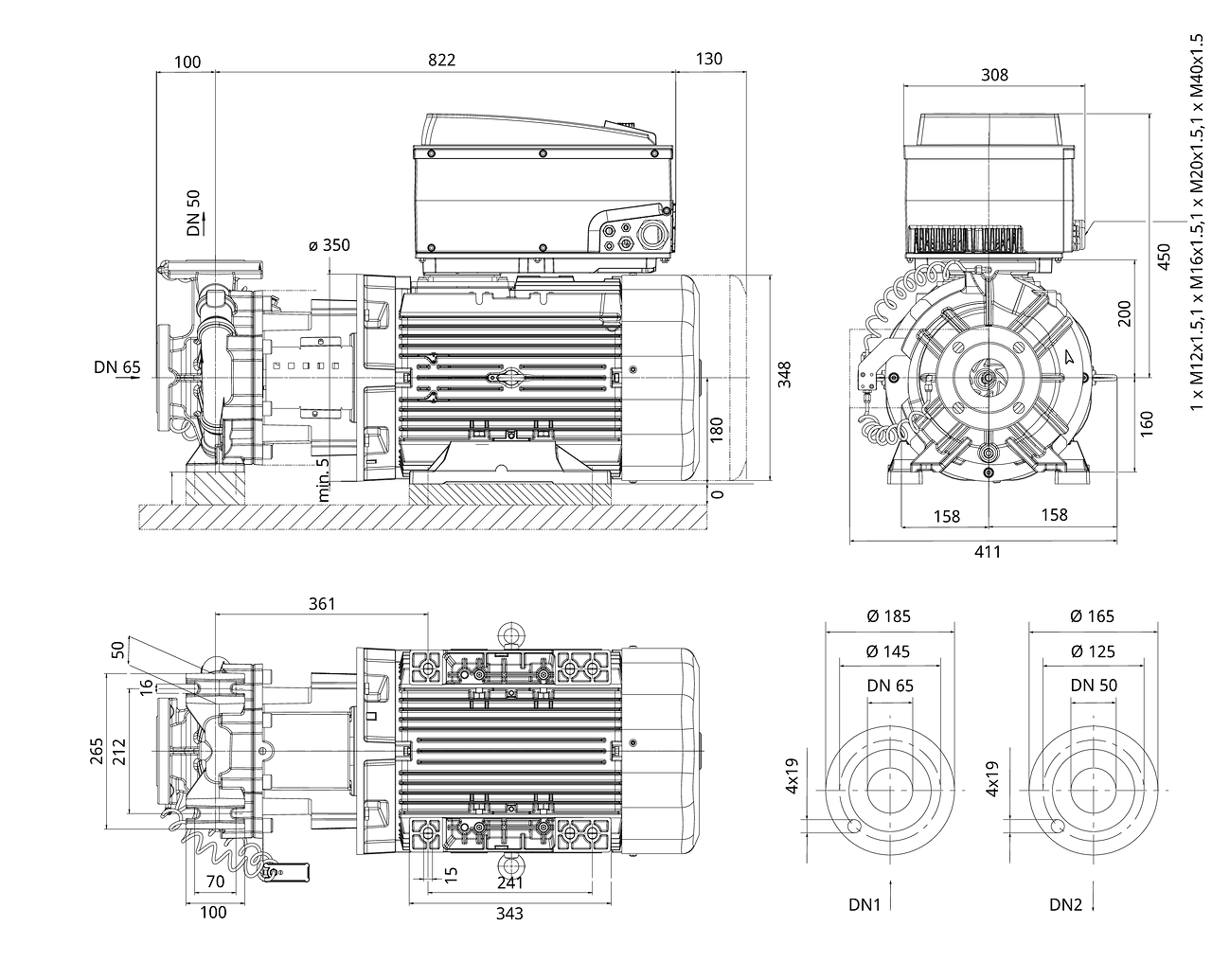

- Spiral housing in monobloc design with flange and housing dimensions according to DIN EN 733, flanges PN 16 — according to EN 1092-2

- Low-oscillation and low-noise monobloc design with lantern, foot on pump housing and rigidly connected standard motor

- All grey cast iron components with cataphoretic coating as standard

- Direction-of-rotation-independent bellows mechanical seal with forced flushing and cavitation-reducing impeller.

- Mechanical seal S1 recommended for water-glycol mixtures with glycol proportions up to max. 50 % by volume and a fluid temperature of -20 °C up to max. +90 °C ... +110 °C and also if there is oil in the water-glycol mixture.

Standard equipment

Pump display for indication of:

- Control mode Δp-c (constant differential pressure), Δp-v (variable differential pressure), PID controller, n-constant (constant speed)

- Setpoint (e.g. differential pressure or speed)

- Error and warning messages

- Actual values (e.g. power consumption, actual value of the sensor)

- Operating data (e.g. operating hours, energy consumption)

- Status data (e.g. status of SSM and SBM relay)

- Device data (e.g. pump name)

- Operating mode (for Y-piece installation only: main/standby operation, parallel operation)

One-button manual operation level for:

- Pump On/Off

- Setpoint and speed adjustment

- Selecting the operation and control mode

- Configuration of operating parameters

- Fault acknowledgement

Additional functions

- Interfaces: Control input «Overriding Off», analogue input 0-10 V, 2-10 V, 0-20 mA, 4-20 mA for constant speed (DDC) or for remote setpoint adjustment, IR interface for wireless communication with operating and service unit Wilo-IR-Monitor/IR-Stick, plug-in slot for Wilo IF modules for connecting to building automation, configurable, potential-free fault and run signal

- Three-phase AC motor with frequency converter

- Integrated dual pump management

- Integrated full motor protection (PTC thermistor sensor) with trip electronics

- Standard condensate drainage holes in the motor housing (closed upon delivery)

- Different operating modes for heating (HV) or air-conditioning (AC) applications

- Access disable on the pump

- Different operation levels: Standard/Service

Accessories

- Supporting blocks for fixing to the base

- IR-Monitor

- IR-Stick

- IF module PLR

- IF module LON

- IF module Modbus

- IF module BACnet

- IF module CAN

- Control systems VR-HVAC/CCe-HVAC/SCe-HVAC

- Differential pressure sensor (DDG) sets 0-10 V for pumps in version ...-R1