Single-stage glanded centrifugal pump in monobloc design for an installation on a base with integrated frequency converter for an electronic control for constant or variable differential pressure (Δp-c/Δp-v). The CronoBloc BL-E has been predominantly designed for pumping heating water (acc. to VDI 2035), cold water and water/glycol mixtures without abrasive substances in heating, air-conditioning and cooling systems.

Design

- Single-stage low-pressure centrifugal pump

- Spiral housing in monobloc design with flange and housing dimensions according to DIN EN 733, flanges PN 16 — according to EN 1092-2

- Low-oscillation and low-noise monobloc design with lantern, foot on pump housing and rigidly connected standard motor

- All grey cast iron components with cataphoretic coating as standard

- Direction-of-rotation-independent bellows mechanical seal with forced flushing and cavitation-reducing impeller.

- Mechanical seal for pumping water up to Tmax = +140 °C. A glycol admixture of 20% to 40% by volume is permissible up to T <= +40 °C. An alternative mechanical seal must be provided in water-glycol mixtures with glycol proportions > 40 % up to max. 50 % by volume and a fluid temperature of > +40 °C up to max. +120 °C or fluids other than water. When using water-glycol mixtures, the use of an S1 variant with a corresponding mechanical seal is generally recommended.

Standard equipment

Pump display for indication of:

- Control mode Δp-c (constant differential pressure), Δp-v (variable differential pressure), PID controller, n-constant (constant speed)

- Setpoint (e.g. differential pressure or speed)

- Error and warning messages

- Actual values (e.g. power consumption, actual value of the sensor)

- Operating data (e.g. operating hours, energy consumption)

- Status data (e.g. status of SSM and SBM relay)

- Device data (e.g. pump name)

- Operating mode (for Y-piece installation only: main/standby operation, parallel operation)

One-button manual operation level for:

- Pump On/Off

- Setpoint and speed adjustment

- Selecting the operation and control mode

- Configuration of operating parameters

- Fault acknowledgement

Additional functions

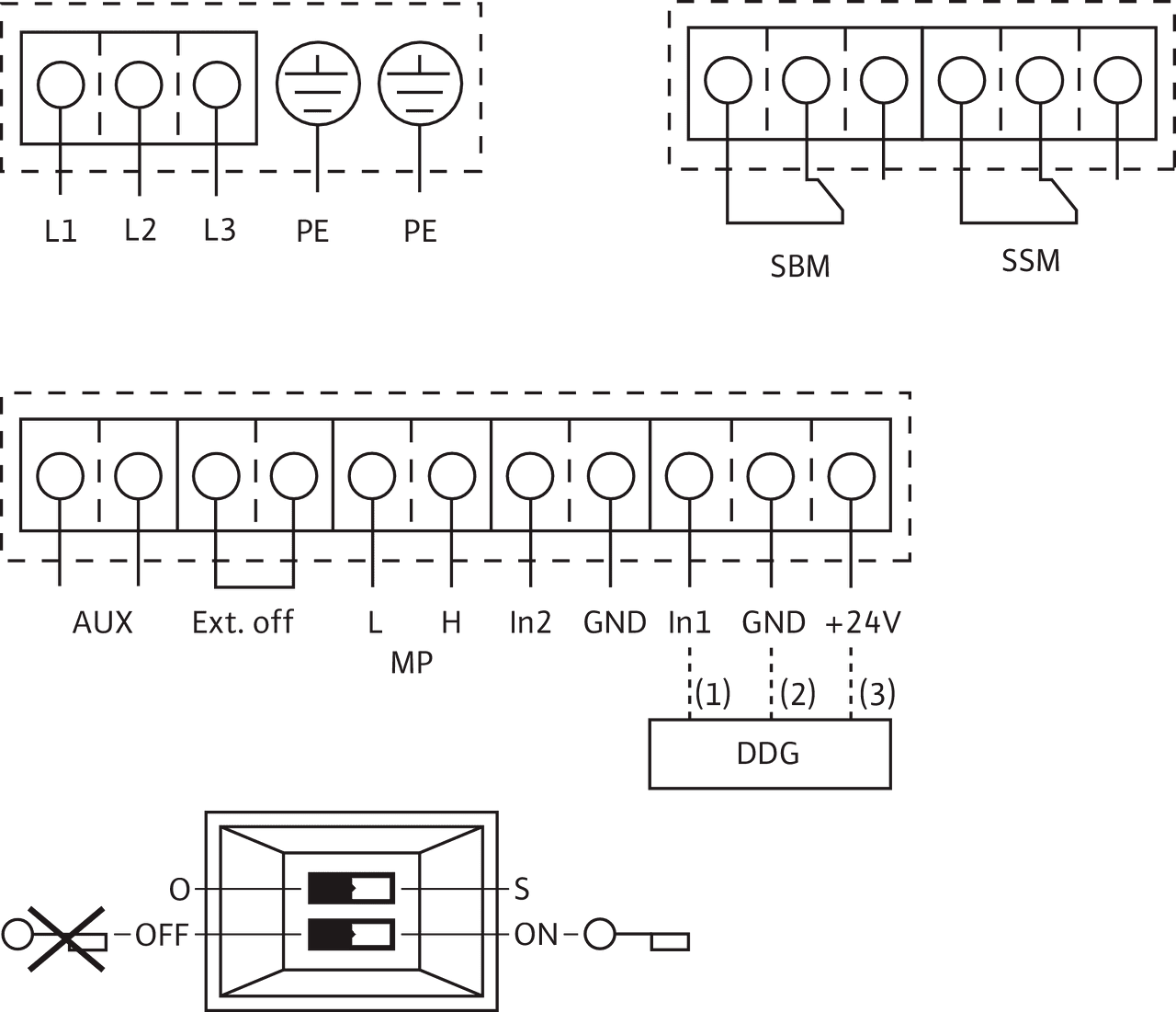

- Interfaces: Control input «Overriding Off», analogue input 0-10 V, 2-10 V, 0-20 mA, 4-20 mA for constant speed (DDC) or for remote setpoint adjustment, IR interface for wireless communication with operating and service unit Wilo-IR-Monitor/IR-Stick, plug-in slot for Wilo IF modules for connecting to building automation, configurable, potential-free fault and run signal

- Three-phase AC motor with frequency converter

- Integrated dual pump management

- Integrated full motor protection (PTC thermistor sensor) with trip electronics

- Standard condensate drainage holes in the motor housing (closed upon delivery)

- Different operating modes for heating (HV) or air-conditioning (AC) applications

- Access disable on the pump

- Different operation levels: Standard/Service

Accessories

- Supporting blocks for fixing to the base

- IR-Monitor

- IR-Stick

- IF module PLR

- IF module LON

- IF module Modbus

- IF module BACnet

- IF module CAN

- Control systems VR-HVAC/CCe-HVAC/SCe-HVAC

- Differential pressure sensor (DDG) sets 0-10 V for pumps in version ...-R1

Materials

Shaft

Stainless steel

Impeller

Grey cast iron

Shaft seal

AQ1EGG

Lantern

Grey cast iron

Pump housing

5.1301/EN-GJL-250 KTL-coated

Dimension, weight

Width

450 mm

Net weight, approx.

168 kg

Height with packaging

636.2 mm

Length with packaging

1200 mm

Width with packaging

800 mm

Length

850 mm

Gross weight, approx.

193 kg

Height

492 mm

Packaging

Pieces per pallet

1

Number per layer

1

Packaging property

Transport packaging

Packaging type

Euro pallet

Product data

Brand

Wilo

Colour

Green

Date of sales availability

2023-04-01

Product description

BL-E65/245-5,5/4

Minimum order quantity

1

Article number

2222346

EAN number

4062679247953

Drive

Protection class motor

IP55

Motor efficiency class

IE4

Rated power

5.5 kW

Power consumption

6000 W

Motor protection

PTC integrated

Interference emission

EN 61800-3

Insulation class

F

Mains connection

3~380 V, 50/60 Hz

Interference immunity

EN 61800-3

Max current

9.8 A

Hydraulic data

Max. fluid temperature

140 °C

Maximum operating pressure

16 bar

Min. fluid temperature

-20 °C

Minimum efficiency index (MEI)

0.4

Max. ambient temperature

40 °C

Min. ambient temperature

0 °C

Note on dimensioning

16 bar to 120 °C, 13 bar to 140 °C

Installation dimensions

Pipe connection on the discharge side

DN 65

Pipe connection on the suction side

DN 80

Approved liquids (other liquids upon request)

Cooling and cold water circulation systems

Yes

Water-glycol mixtures (at 20 – 40 vol. % glycol and fluid temperature ≤ 40 °C)

Yes

Heating water (as per VDI 2035)

Yes

Heat carrier oil

Special version at additional charge

| Артикул | Название | Цена | ||

|---|---|---|---|---|

| 2221116 | BL-E80/295-15/4-R1 | Цена по запросу | ||

| 2221117 | BL-E80/295-15/4-R1-S1 | Цена по запросу | ||

| 2221118 | BL-E100/250-15/4 | Цена по запросу | ||

| 2221119 | BL-E100/250-15/4-S1 | Цена по запросу | ||

| 2221120 | BL-E100/250-15/4-R1 | Цена по запросу | ||

| 2221121 | BL-E100/250-15/4-R1-S1 | Цена по запросу | ||

| 2221122 | BL-E100/240-11/4 | Цена по запросу | ||

| 2221123 | BL-E100/240-11/4-S1 | Цена по запросу | ||