Hydro EN 65-200/185 S2JS ADL-U1

The Hydro EN pump set is designed in compliance to EN 12845 standard for operation with clean fresh water in automatic sprinkler systems, hydrant networks and compartments for installation of firefighting pump sets.

Hydro EN 65-200/185 S2JS ADL-U1

Pressure booster pump sets are designed for automatic sprinkler systems, according to EN 12845, in addition to other relevant industry standards.

The pumps sets are designed for fire extinguishing systems with clean water and for single or combined water supplies. It is compact, robust and modular system supplied in pre-assembled macro blocks to make transport, handling and installation easy. Communication is guaranteed through ModBus module.

The main pumps have end-suction hydraulics. They are fitted with corrosion-resistant material and replaceable wearing parts, back pull-out design through spacer coupling, fitted with high grade mechanical seals and internally tested at the factory according to QCP protocols.

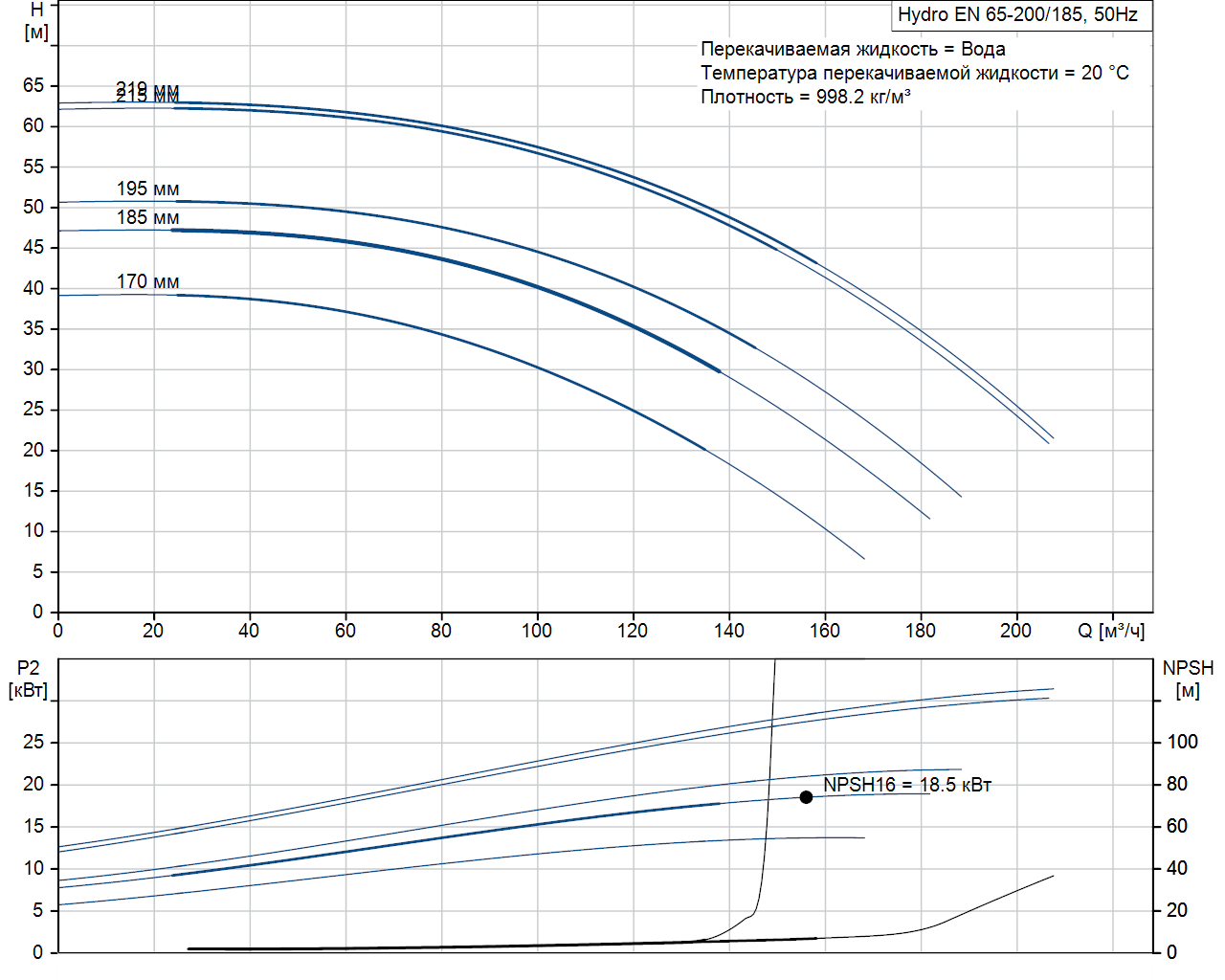

The main pumps are equipped with IEC squirrel cage IE3 electric motors that deliver, in continuous operation, at least the power required at the flow corresponding to the NPSHr value equal to 16 m.

The hydraulic components are designed to minimize the pressure loss and the water speed to meet the requirements at the flow rate values stated on the performance curve.

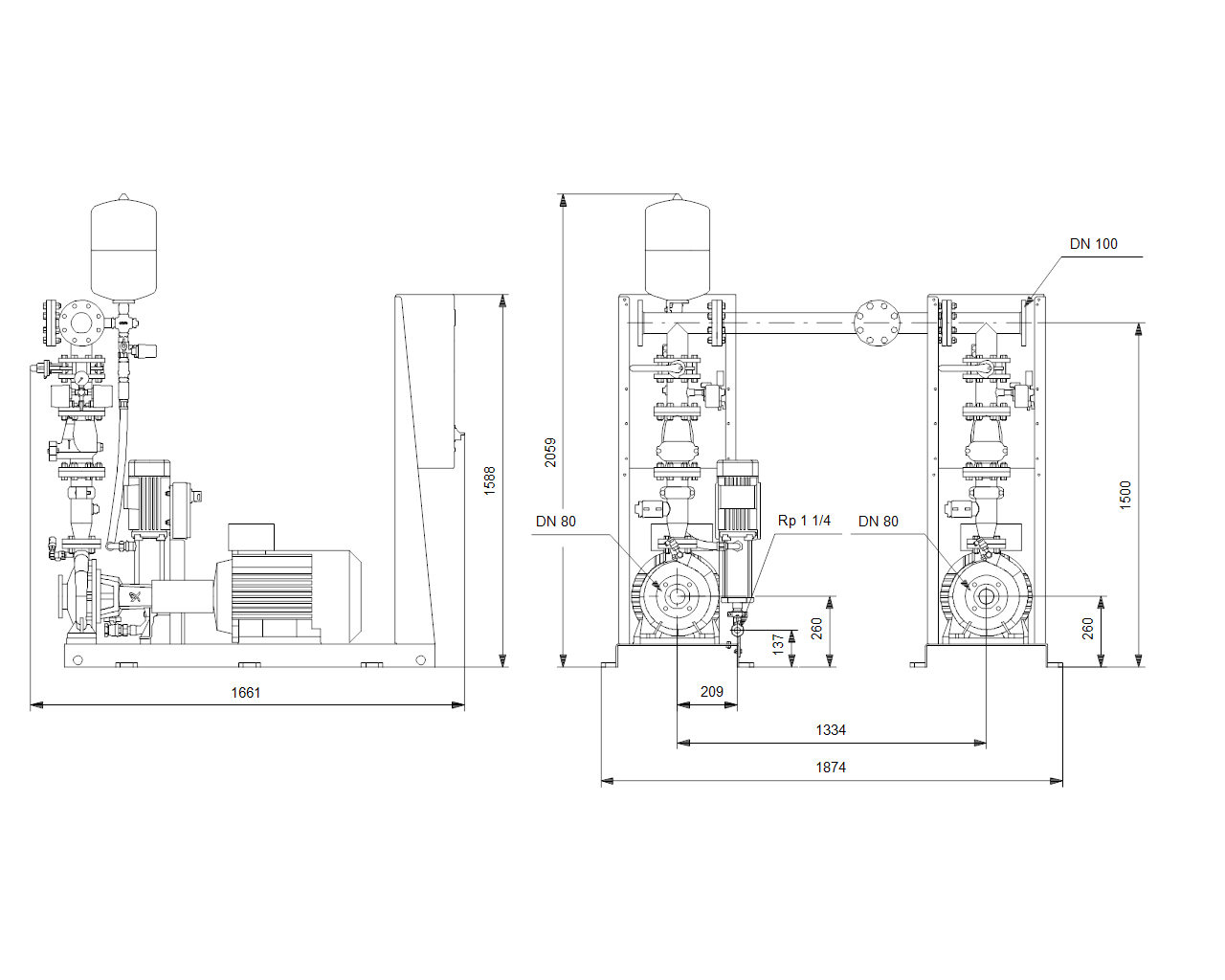

The system contains the following components (unless otherwise specified): • Two hydraulics coupled with drivers • Two microprocessor-based control panels • One pressure maintenance pump and related independent control panel • One modular discharge manifold • Two concentric tapered adapters • Two grooved joints • Direct connection port for room sprinkler • Two non-return valves • Two isolating valves • Two drain test valves • Two pump starting assembly pack (two pressure switches, glycerin-filled pressure gauge, isolating valve, bypass line with non-return valve and drain valve) • Two pressure sensing switches (pump running) • Pressure vessel • A set of Jockey pump fittings (connection for priming, non-return valve, two isolating valves and a pressure switch).

For more components, contact Grundfos.

The two main pumps are configured in a duty / stand-by configuration.

Each pumping unit is mounted on a separate baseplate to reduce stress from one unit to the other while assuring layout flexibility. This layout ensures easy access to the narrow pump room entry and handling in case of extraordinary maintenance needs and keeps the system protected.

All the items are wired and fitted at the factory within the same unit skid, except for larger main control panels that are supplied loose with proper signals and cable entry tags.

Pump, driver, jockey pump and controllers (unless large size) are anchored on a robust electro-welded baseplate. They are painted RAL 3000 and designed to withstand all static and dynamic stress. The baseplates are designed with holes and anchoring lugs for an easy and safe handling ensuring optimal fastening to the plinth or concrete foundation.

For further product information, please tick off «Tender text» under «Print/PDF».