Compact pressure-boosting system according to DIN 1988 and DIN EN 806, for direct or indirect connection. Consisting of non-self-priming, vertically-mounted, stainless steel high-pressure multistage centrifugal pumps in glandless pump versions connected in parallel, for which each pump is fitted with a frequency converter. Ready for connection with stainless steel pipework, mounted on a base frame, including control device with all necessary measurement and adjustment equipment.

For fully automatic water supply and pressure boosting in residential, commercial and administrative buildings, hotels, hospitals, department stores and for industrial systems.

For pumping drinking water, process water, cooling water, firefighting water (apart from fire-fighting systems in accordance with DIN 14462 and with the approval of the local fire protection authorities) or other types of industrial water that do not attack the materials either chemically or mechanically and do not contain abrasive or long-fibre constituents.

Special features/Product advantages

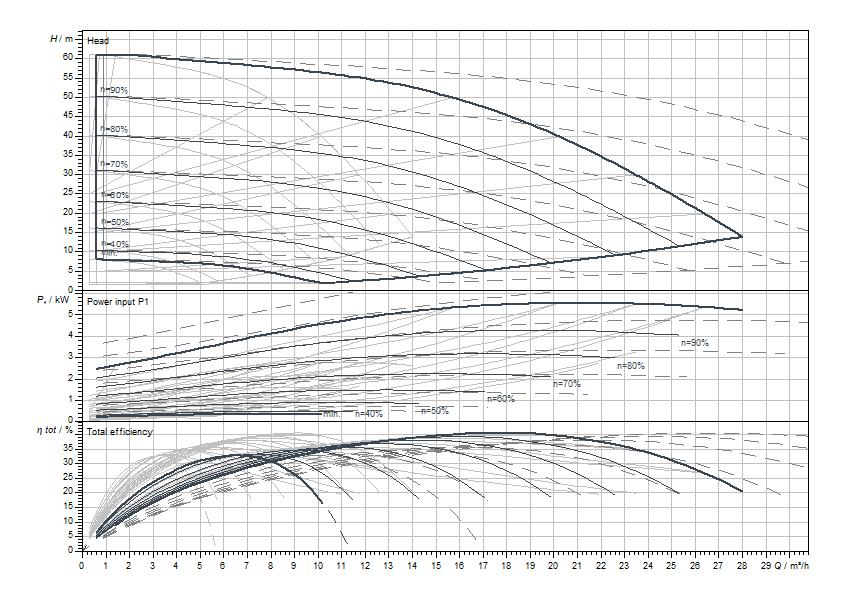

- Optimum pump load adjustment due to pressure-variable (pv) control mode and parallel synchronous speed control for higher energy savings

- Up to 20 dB[A] quieter operation than conventional systems with comparable hydraulic output

- Disproportionately large frequency converter control range from 20 Hz to a maximum of 50 Hz

- Maintenance-free pump design without mechanical seals

- High reliability thanks to various protective features including overload protection, dry-running protection and automatic deactivation

- Easy setting and operation with the SCe switchgear thanks to LCD display and green adjustment button

- Drinking water approvals for all components that come in contact with the fluid

- Ready for integration into building automation with the SCe switchgear via standard Modbus RTU

Equipment/function

2 — 4 pumps per system of the MVISE series with glandless motors speed controlled via integrated frequency converters on each pump.

SCe switchgear ensures automatic control of the complete pressure-boosting system.

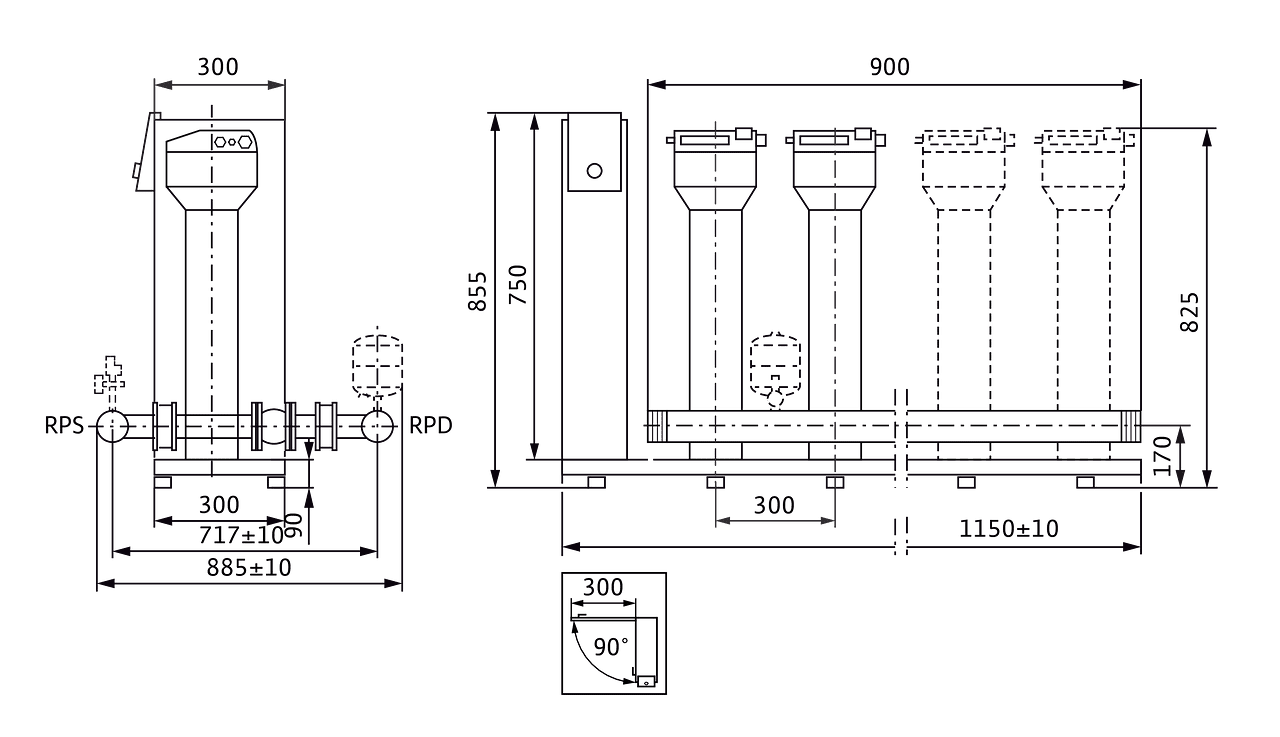

Complete assembly mounted on galvanised steel, height-adjustable base frame.

All components in contact with fluid are corrosion- resistant.

On the discharge side:

- Shut-off valve at each pump

- Non-return valve at each pump

- Diaphragm pressure vessel 8 l, PN 16

- Pressure sensor 4 ... 20 mA

- Pressure gauge

On the suction side:

- Shut-off valve at each pump

- Pressure sensor 4 ... 20 mA

- Pressure gauge

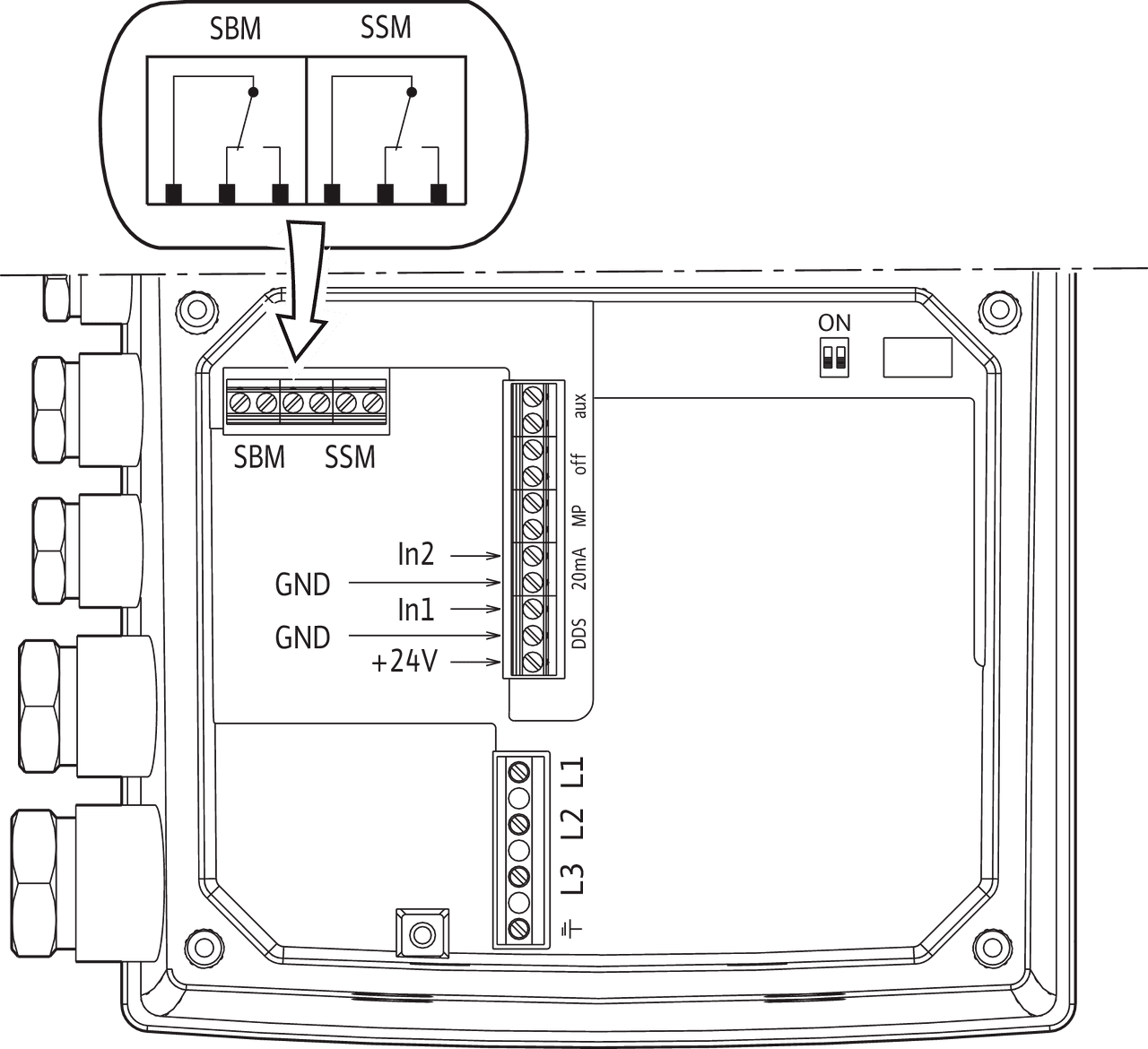

Smart Controller (SCe) in a sheet metal enclosure, protection class IP54, consisting of an internal control voltage supply unit, microprocessor with Soft PLC, analogue and digital inputs and outputs, for control of electronic pumps with frequency converters.

A working area of 1 m around the system is recommended in order to facilitate the maintenance process.

Operation/display

- LC display (backlit) for display of the operating data, controller parameters, operating statuses of the pumps, error messages and history memory

- Menu navigation with symbols and menu numbers

- LEDs for display of system status (operation/fault)

- Factory-preset parameters for easy commissioning/start-up

- Setting of operating parameters and acknowledgement of fault messages using Green Button Technology

- Lockable main switch

- Operation with/without standby pump selectable by customer service

- Elapsed time indicator for each pump and for entire system

- Switching cycle counter for each pump and for entire system

- Fault memory for the last 16 faults

Control

- Fully automatic control for 1 — 4 frequency-controlled pumps by means of setpoint/actual value comparison

- Setpoint changeover: Second setpoint can be activated by contact

- Automatic, load-sensitive cut-in of 1 to n peak-load pump(s) depending on the control variable «pressure constant» (p-c) or «pressure variable» (p-v)

- 2 parameter sets selectable, easy menu (setpoint & control mode) or expert menu (operation and control parameters)

- Operating mode of the pumps freely selectable (manual, off, automatic)

- Automatic, configurable pump cycling

- Standard setting: Impulse — The base-load pump is cycled at each new demand, regardless of operating hours

- Alternatively: Pump cycling dependent on operating hours, cycling of the base-load pump after the specified operating hours

- Automatic, configurable pump test run (pump kick)

- Can be activated/deactivated

- Time between two pump test runs is freely programmable

- Disabling times can be programmed as desired

- Speed can be adjusted as desired

Monitoring

- Actual value of the system is output via a 0 — 10 volt analogue signal for external measurement/display applications, 10 volt depending on the sensor range value

- 4 — 20 mA sensor signal (conductivity test of the sensor cable) for control variable actual value

- The pump mains power feed is protected via the circuit breaker

- Automatic switchover to standby pump in the event of an operating pump fault

- Monitoring of maximum and minimum system values with adjustable time delays and limits

- Zero-flow test for switching off the system when no water is being drawn off (adjustable parameters)

- Pipe filling function for filling empty pipes (initial filling of the consumer network)

- Protection against low water level through standard 4..20 mA pressure sensor on the suction side

- Protection against low water level via switching contact e.g. for float switch

- Automatic shutdown of pumps if fault occurs or operation at preset emergency operation speed

Interfaces

- Potential-free contacts for SBM/SSM collective run and collective fault signals

- Logic reversal can be applied to SBM and SSM

- Contacts for external on/off, low water and second setpoint

- External on/off via contact for deactivation of the system's automatic mode

Optional accessories (factory installation or retrofitting after technical checks)

- Individual operation/fault message

- Signal converter for 0/2 — 10 V to 0/4 — 20 mA

- Communication module GSM (SC)

- Internet-based WiloCare remote maintenance

Recommended accessories (to be ordered separately)

- Flexible connection pipes or compensators

- Threaded caps for systems with threaded joint tubing

Bus systems (optional)

- LON bus, Modbus TCP, BACnet MSTP, BACnet IP

Standards followed

- Specifications for drinking water installations (TRWI) DIN 1988 (EN 806)

- Diaphragm pressure vessel/diaphragm expansion tank DIN 4807

- Electronic equipment for use in power installations, EN 50178

- Electrical Equipment of Machines EN 60204-1

- Safety of household and similar electrical devices EN 60335-1

- Low-voltage switchgear and controlgear assemblies EN 60439-1/61439-1

- EMC — Interference immunity for industrial environments EN 61000-6-2

- EMC — Interference emission for residential, commercial and light-industrial environments (EN 61000-6-3)

| Артикул | Название | Цена | ||

|---|---|---|---|---|

| 2550753 | SiBoost Smart 3MVISE406 | Цена по запросу | ||

| 2550763 | SiBoost Smart 4MVISE806 | Цена по запросу | ||

| 2550762 | SiBoost Smart 4MVISE803 | Цена по запросу | ||

| 2550761 | SiBoost Smart 4MVISE410 | Цена по запросу | ||

| 2550760 | SiBoost Smart 4MVISE406 | Цена по запросу | ||

| 2550759 | SiBoost Smart 4MVISE404 | Цена по запросу | ||

| 2550758 | SiBoost Smart 4MVISE210 | Цена по запросу | ||

| 2550757 | SiBoost Smart 4MVISE206 | Цена по запросу | ||

| 2550756 | SiBoost Smart 3MVISE806 | Цена по запросу | ||

| 2550755 | SiBoost Smart 3MVISE803 | Цена по запросу | ||

| 2550754 | SiBoost Smart 3MVISE410 | Цена по запросу | ||

| 2550743 | SiBoost Smart 2MVISE206 | Цена по запросу | ||

| 2550752 | SiBoost Smart 3MVISE404 | Цена по запросу | ||

| 2550751 | SiBoost Smart 3MVISE210 | Цена по запросу | ||

| 2550750 | SiBoost Smart 3MVISE206 | Цена по запросу | ||

| 2550749 | SiBoost Smart 2MVISE806 | Цена по запросу | ||

| 2550748 | SiBoost Smart 2MVISE803 | Цена по запросу | ||

| 2550747 | SiBoost Smart 2MVISE410 | Цена по запросу | ||

| 2550746 | SiBoost Smart 2MVISE406 | Цена по запросу | ||

| 2550745 | SiBoost Smart 2MVISE404 | Цена по запросу | ||

| 2550744 | SiBoost Smart 2MVISE210 | Цена по запросу | ||