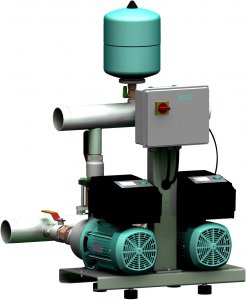

Wilo-Comfort-Vario COR MHIE.../MS

Your advantages Easy installation thanks to compact system with two or three multistage horizontal MHIE pumps with integrated air-cooled frequency converter High operational reliability thanks to full motor protection with PTC thermistor sensor and automatic dry-running detection Drinking water approval (ACS) for pumps with components made of stainless steel that come into contact with the fluid High operational reliability thanks to master/slave function Recommended services Maintenance Commissioning WiloCare

| Артикул | Наименование | Цена | ||

|---|---|---|---|---|

| 4231051 | COR-3 MHIE 203/MS | Цена по запросу | ||

| 4231060 | COR-3 MHIE 1602/MS | Цена по запросу | ||

| 4231059 | COR-3 MHIE 803/MS | Цена по запросу | ||

| 4231058 | COR-3 MHIE 802/MS | Цена по запросу | ||

| 4231057 | COR-3 MHIE 406/MS | Цена по запросу | ||

| 4231056 | COR-3 MHIE 404/MS | Цена по запросу | ||

| 4231055 | COR-3 MHIE 403/MS | Цена по запросу | ||

| 4231054 | COR-3 MHIE 402/MS | Цена по запросу | ||

| 4231053 | COR-3 MHIE 206/MS | Цена по запросу | ||

| 4231052 | COR-3 MHIE 205/MS | Цена по запросу | ||

| 4231041 | COR-2 MHIE 203/MS | Цена по запросу | ||

| 4231050 | COR-2 MHIE 1602/MS | Цена по запросу | ||

| 4231049 | COR-2 MHIE 803/MS | Цена по запросу | ||

| 4231048 | COR-2 MHIE 802/MS | Цена по запросу | ||

| 4231047 | COR-2 MHIE 406/MS | Цена по запросу | ||

| 4231046 | COR-2 MHIE 404/MS | Цена по запросу | ||

| 4231045 | COR-2 MHIE 403/MS | Цена по запросу | ||

| 4231044 | COR-2 MHIE 402/MS | Цена по запросу | ||

| 4231043 | COR-2 MHIE 206/MS | Цена по запросу | ||

| 4231042 | COR-2 MHIE 205/MS | Цена по запросу | ||

Design

Pressure-boosting system with 2 to 3 non self-priming stainless steel high-pressure multistage centrifugal pumps switched in parallel with integrated frequency converter

Application

- Fully automatic water supply and pressure boosting in inlet mode, either from the public water supply network or from a tank, for domestic, commercial, industrial and municipal applications (e.g. residential, office, administration buildings, hotels, hospitals, trades, industry, water supply companies)

- Pumping drinking water, process water, cooling water or other industrial water, which does not affect the materials used, neither chemically nor mechanically, and does not have any abrasive or long-fibre constituents

Equipment/function

- 2 — 3 MHIE pumps per system

- Continuous control mode by use of pumps with integrated frequency converters

- Components that come in contact with the fluid are corrosion-resistant

- Galvanised base frame with height-adjustable vibration absorbers for insulation against structure-borne noise

- Stop valve on every pump on the suction and pressure sides

- Non-return valve, pressure side

- Diaphragm pressure vessel 8 l, PN 10, on the pressure side

- Pressure sensor, on the discharge side

- Pressure gauge optional, on the suction side

- Pressure gauge, discharge side

- Low-water cut-out switchgear, optional

- Switchgear with IP54 plastic housing

Typekey

NO VALUE |

Technical data

- Mains connection 3~400 V +-10%, 50 Hz; 3~380/440 V +-10 %, 60 Hz (other versions on request)

- Max. fluid temperature 50 °C (70 °C optional)

- Max. ambient temperature 40 °C

- Operating pressure 10 bar

- Inlet pressure 6 bar

- Discharge-side nominal connection diameter R 2"/DN 100

- Intake-side nominal connection diameter R 2"/DN 100

- Speed range 1200 — 3770 rpm

- Protection class IP54

- Fuse protection on mains side A, AC 3 according to motor power and EVU regulations

- Approved fluids (other fluids on request). Approved fluids are normally waters which do not corrode the materials used, neither chemically nor mechanically, and do not contain any abrasive or long-fibre constituents.

- Cooling water

- Drinking and process water

Materials

Single pump:

- Impellers, stage chambers and pump housing made of stainless steel 1.4301/1.4404

- Shaft of stainless steel 1.4404

- EPDM gasket (EP851)/FKM (Viton)

- Mechanical seal made of tungsten carbide/carbon

- Bearing of tungsten carbide

- Pump support foot made of aluminium

Construction

- Base frame: galvanised and with height-adjustable vibration absorbers for comprehensive insulation against structure-borne noise; other versions on request

- Pipework: complete pipework made of stainless steel, suitable for the connection of all piping materials used in building services; the pipework dimensions must correspond to the overall hydraulic performance of the pressure-boosting system

- Pumps: 2 to 3 pumps from the MHIE series 2.., 4.., 8.. and 16.. switched in parallel; the frequency converter adapted to the pump motor enables continuous auto control for all pumps in these series; all pump components coming into contact with liquids are made of 1.4301/1.4404 stainless steel

- Valves: Each pump is equipped on the suction and pressure side with a shut-off valve with ACS approval mark or annular shut-off valves and a pressure-side non-return valve with ACS approval

- Diaphragm pressure vessel: 8 l/PN 10 on the discharge side with butyl rubber diaphragm, completely safe according to the food safety regulations; for test and inspections purposes, having ball valve and drain and throughflow fitting according to DIN 4807

- Pressure sensor: 4 to 20 mA, on the discharge side

Scope of delivery

- Factory-mounted, ready for connection pressure-boosting system checked for functionality and impermeability

- Packaging

- Installation and operating instructions

Typekey

NO VALUE |

Technical data

- Mains connection 3~400 V +-10%, 50 Hz; 3~380/440 V +-10 %, 60 Hz (other versions on request)

- Max. fluid temperature 50 °C (70 °C optional)

- Max. ambient temperature 40 °C

- Operating pressure 10 bar

- Inlet pressure 6 bar

- Discharge-side nominal connection diameter R 2"/DN 100

- Intake-side nominal connection diameter R 2"/DN 100

- Speed range 1200 — 3770 rpm

- Protection class IP54

- Fuse protection on mains side A, AC 3 according to motor power and EVU regulations

- Approved fluids (other fluids on request). Approved fluids are normally waters which do not corrode the materials used, neither chemically nor mechanically, and do not contain any abrasive or long-fibre constituents.

- Cooling water

- Drinking and process water

Materials

Single pump:

- Impellers, stage chambers and pump housing made of stainless steel 1.4301/1.4404

- Shaft of stainless steel 1.4404

- EPDM gasket (EP851)/FKM (Viton)

- Mechanical seal made of tungsten carbide/carbon

- Bearing of tungsten carbide

- Pump support foot made of aluminium

Construction

- Base frame: galvanised and with height-adjustable vibration absorbers for comprehensive insulation against structure-borne noise; other versions on request

- Pipework: complete pipework made of stainless steel, suitable for the connection of all piping materials used in building services; the pipework dimensions must correspond to the overall hydraulic performance of the pressure-boosting system

- Pumps: 2 to 3 pumps from the MHIE series 2.., 4.., 8.. and 16.. switched in parallel; the frequency converter adapted to the pump motor enables continuous auto control for all pumps in these series; all pump components coming into contact with liquids are made of 1.4301/1.4404 stainless steel

- Valves: Each pump is equipped on the suction and pressure side with a shut-off valve with ACS approval mark or annular shut-off valves and a pressure-side non-return valve with ACS approval

- Diaphragm pressure vessel: 8 l/PN 10 on the discharge side with butyl rubber diaphragm, completely safe according to the food safety regulations; for test and inspections purposes, having ball valve and drain and throughflow fitting according to DIN 4807

- Pressure sensor: 4 to 20 mA, on the discharge side

Scope of delivery

- Factory-mounted, ready for connection pressure-boosting system checked for functionality and impermeability

- Packaging

- Installation and operating instructions